This blog post explores the technology behind Blast Proof Windowss, a critical safety feature in buildings prone to explosions or other high-impact incidents. We delve into their construction, materials used, testing procedures, and the science that makes them resilient. The post aims to educate readers on how these windows contribute to creating safer living and working environments.

1. The Anatomy of a Blast Proof Windows: What Makes it Different?

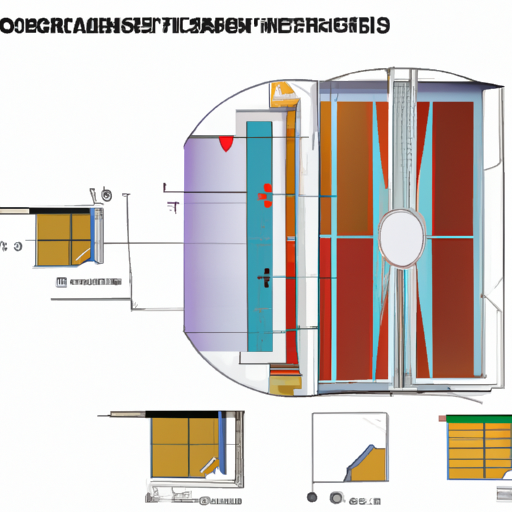

Blast Proof Windowss are a crucial component of building safety in high-risk areas. Unlike traditional windows, Blast Proof Windowss are specifically designed to withstand the impact of an explosion. But what sets them apart? To understand the technology behind Blast Proof Windowss, it is essential to examine their unique anatomy.

First and foremost, Blast Proof Windowss are constructed using specialized materials that can withstand the force of an explosion. These materials typically include layers of laminated glass, polycarbonate, and sometimes even a combination of both. The multiple layers are crucial as they help distribute the force of the blast and prevent the window from shattering into dangerous shards. Additionally, the materials used in Blast Proof Windowss are often reinforced with high-strength metals or polymers to further enhance their resistance.

Another key feature of Blast Proof Windowss is the framing system. Unlike traditional windows, Blast Proof Windowss are typically installed with a robust framing system that can withstand the intense pressure generated by an explosion. The framing system is designed to absorb and distribute the force of the blast, minimizing the risk of structural damage and ensuring the window remains intact.

Furthermore, Blast Proof Windowss are often equipped with specialized glazing techniques. This involves bonding the layers of glass or polycarbonate together using a combination of adhesives and interlayers. The goal is to create a strong and flexible barrier that can absorb the energy of an explosion and prevent the window from breaking apart. Additionally, some Blast Proof Windowss may also incorporate advanced technologies such as laminated films or coatings that further enhance their resistance to blasts.

1. A cross-sectional diagram of a Blast Proof Windows illustrating its multiple layers.

2. 'Glass that Doesn't Shatter?': The Science of Blast-Proof Materials

The science behind blast-proof materials is fascinating and intricate. One of the key components of Blast Proof Windowss is the use of laminated glass. Laminated glass consists of multiple layers of glass that are bonded together using a strong interlayer, typically made of polyvinyl butyral (PVB) or ethylene-vinyl acetate (EVA). This interlayer acts as a barrier, preventing the glass from shattering upon impact. When an explosion occurs, the interlayer absorbs the energy and disperses it throughout the glass, minimizing the risk of breakage.

In addition to laminated glass, Blast Proof Windowss may also incorporate polycarbonate materials. Polycarbonate is a durable, transparent plastic that is incredibly resistant to impact. It is often used in combination with laminated glass to provide an extra layer of protection. When a blast occurs, the polycarbonate layer absorbs and disperses the energy, preventing the glass from shattering and maintaining the structural integrity of the window.

To further enhance the blast resistance of these materials, advanced technologies are used. For example, some laminated glass and polycarbonate materials may be coated with a thin film that adds an extra layer of strength and flexibility. This film can help absorb and disperse the energy of an explosion, preventing the window from breaking apart.

3. Putting Blast Proof Windowss to the Test: How Do We Know They Work?

Testing Blast Proof Windowss is a crucial step in ensuring their effectiveness and reliability. These windows undergo rigorous testing procedures to simulate real-life blast scenarios and evaluate their performance. One common method used is the shock tube test, where a high-pressure shockwave is generated to mimic the effects of an explosion. The Blast Proof Windows is placed in the path of the shockwave, and its response is carefully observed and measured.

In addition to shock tube testing, Blast Proof Windowss may also be subjected to other types of tests, such as projectile impact tests and pressure tests. Projectile impact tests involve firing projectiles at the window to assess its ability to withstand flying debris during an explosion. Pressure tests, on the other hand, involve subjecting the window to high-pressure conditions to evaluate its resistance to blast pressure.

To ensure the accuracy and reliability of these tests, they are conducted in specialized laboratories and facilities that are equipped with advanced measurement and monitoring systems. These systems capture data such as the force and pressure exerted on the window, the displacement of the glass, and the overall structural integrity.

Furthermore, Blast Proof Windowss are often tested and certified by independent third-party organizations that specialize in evaluating the performance of security products. These organizations verify whether the windows meet specific industry standards and criteria for blast resistance.

3. An image capturing the moment of a Blast Proof Windows being tested under extreme conditions.

4. Beyond Blast Resistance: Additional Benefits of Blast Proof Windowss

Blast Proof Windowss offer more than just protection against explosions. They have several additional benefits that make them an attractive choice for buildings in high-risk areas or those seeking enhanced security measures.

Firstly, Blast Proof Windowss provide excellent sound insulation. The multiple layers of glass and interlayers used in their construction help to reduce noise transmission significantly. This feature is particularly advantageous for buildings located near busy streets, airports, or other noisy environments, as it helps create a more peaceful and comfortable indoor environment.

Secondly, Blast Proof Windowss offer enhanced energy efficiency. The multiple layers of glass, along with the interlayers, provide excellent insulation properties that help keep the indoor temperature stable. This reduces the reliance on heating and cooling systems, resulting in lower energy consumption and cost savings for building owners.

Additionally, Blast Proof Windowss provide increased protection against forced entry and break-ins. The strong and durable materials used in their construction make it extremely difficult for intruders to penetrate the windows. This added layer of security gives building occupants peace of mind, knowing that their property and belongings are well-protected.

Furthermore, Blast Proof Windowss offer improved UV protection. The multiple layers of glass help to block out harmful ultraviolet (UV) rays, which can cause fading and damage to furniture, artwork, and other valuable items. By reducing UV penetration, Blast Proof Windowss help preserve the integrity and longevity of interior spaces, ensuring that they remain vibrant and appealing for years to come.

Understanding the technology behind Blast Proof Windowss offers insight into the meticulous engineering and rigorous testing that goes into creating this crucial safety feature. The advanced materials and design strategies used not only withstand high-impact blasts but also offer added benefits like noise reduction and UV protection. As technology advances, these windows continue to evolve, offering even greater levels of safety and resilience.

למידע אודות Understanding the Technology Behind Blast Proof Windows נא לגלוש לאתר gg-ds.com